As the progres of the tims, the technology and ability on manufacturing on Display Fixtures are changing better with each passing day. Customers always want perfect detail fixtures in the store to display the perfect products on sale. We can understand why customers are so extremely highly request the fixtures as well as their products. Because the fixtures and the products complement and shine each other. How to tell display stands or floor racks are of high quality? There are many details such as welding, grinding, powder coating,plating and packing. They are all very important. Here are going to talk about the welding and grinding on metal display fixtues manufacturing in detail.

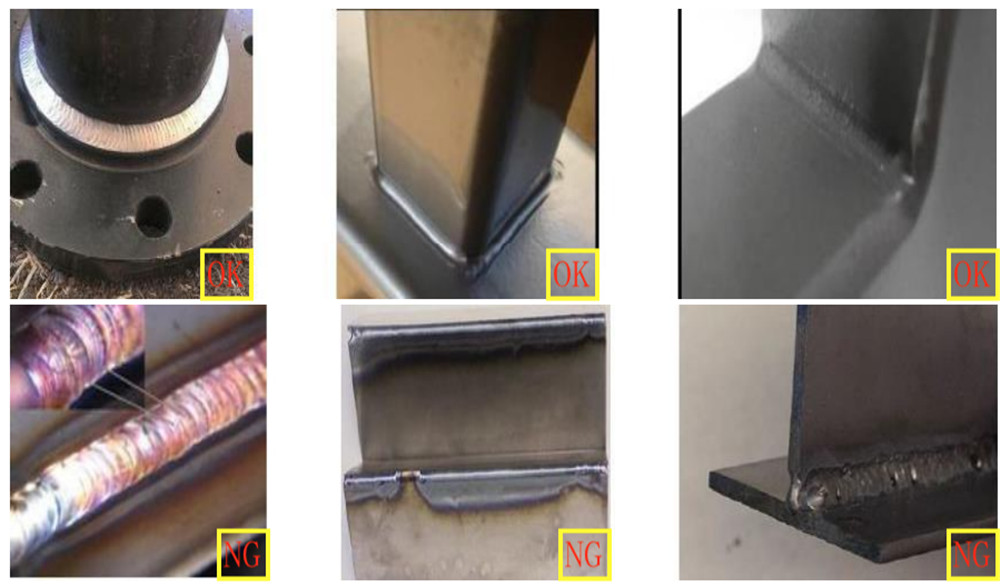

As to welding, there are TIG welding, MIG welding and spot welding. Which one to use depends on the structure and the function. For TIG weld, it shall be continuous and smooth as shown below. It should be free from discolouration, very visible pores, striations and should not burn the welded pieces.

The fillet of a good MIG weld shall be continuous and smooth, as shown below. It should be free of very visible pores and should not burn the welded pieces.

A good spot weld shall be smooth and flat on the presentation face.

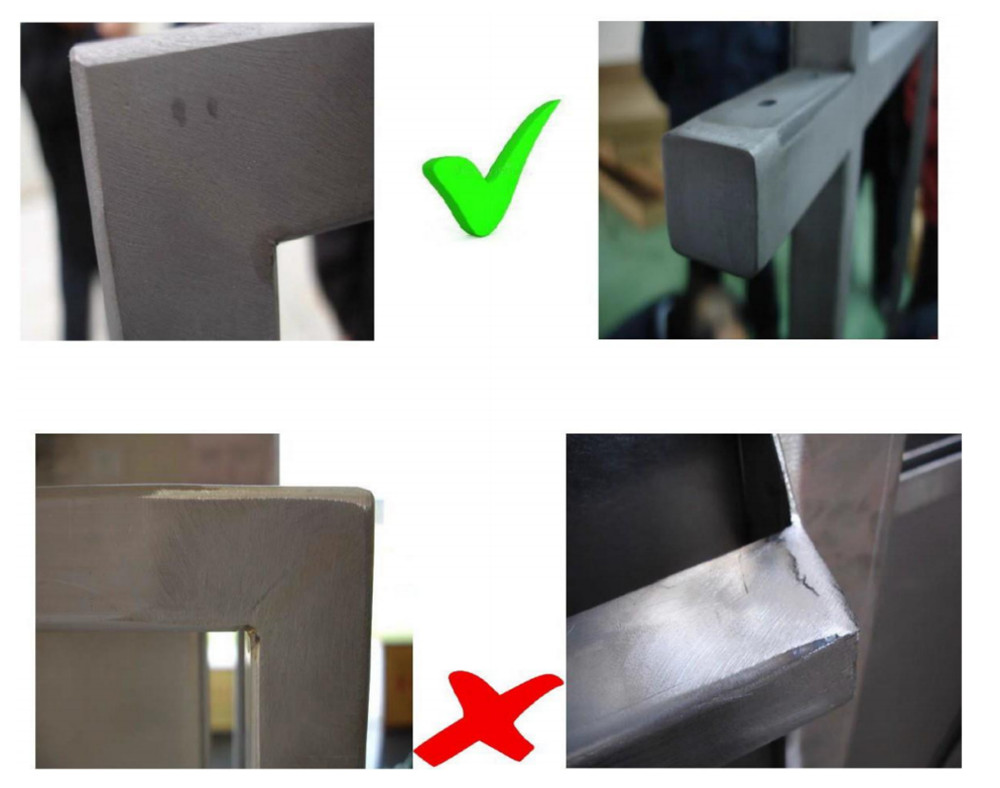

Flat surfaces: Grinding shall be smooth and level.

Surfaces with radius: Grinding shall be smooth and level and shall blend in with other surfaces.

When the welding and grinding quality made high level enough, no matter it is power coating or plating, it can help present a beautiful display function. Ever Glory Fixtures as a responsible production enterprise, pay great attention to the quality of our products. Hope this report can help more people to know more about the display fixtures and we will share more in future.

Post time: Jan-05-2023